InnoAquaTech Study Visit to Denmark – Aquaculture technology and feed innovation

After yet another successful InnoAquaTech Study Visit to Belgium in November 2018, our final excursion took place on the 22ndand 23rdMay 2019. The event, which was planned by Hilary Karlson (Danish Technological Institute), brought together participants from Denmark, Germany, Lithuania and Poland. This time the consortium went to Jutland – where key aquaculture players and technology providers are based.

This final InnoAquaTech study tour to the Danish peninsular of Jutland aimed to give SMEs in the South Baltic Region an insight into Danish state-of-the-art aquaculture technology and the people behind. 20 participants from the South Baltic Region learned about the innovative approaches of the Danish aquaculture, aqua-technology and feed sectors, making new contacts and visiting large-scale RAS production and cutting-edge feed development companies.

This final InnoAquaTech study tour to the Danish peninsular of Jutland aimed to give SMEs in the South Baltic Region an insight into Danish state-of-the-art aquaculture technology and the people behind. 20 participants from the South Baltic Region learned about the innovative approaches of the Danish aquaculture, aqua-technology and feed sectors, making new contacts and visiting large-scale RAS production and cutting-edge feed development companies.

First stop on the 22ndMay was to FREA Aquaculture Solutions– where we were greeted by sales and administration manager Peter Jessen. FREA has a hatchery for rainbow trout and a grow out facility based on RAS raceways. All the water for the facility comes from drains under the surrounding 100 hectares of land. Only when necessary is tap water employed at this site. The sludge and wastewater from the fish production is used to water and fertilize the crops on the surrounding land and these crops in turn are used for energy production.

FREA has an annual production of 1200 to 1600 tons of market-sized fish, which are delivered for further processing. In addition, about 2400 tons are produced as seedling fish, which are then transferred to other aquaculture facilities. The fish fry is produced in batches and these are kept in their groups as they are transferred from small raceways to increasingly larger raceways with just one size-sorting until finally they are ready for harvest. The fish are sold with the ASC label. Water quality within the culture units of the facility is maintained by the application of different water treatment compartments such as aerobic biofilters, stripping and oxygenation tanks as well as pH adjustments.

Raceway grow out facility at FREA Aquaculture Solutions

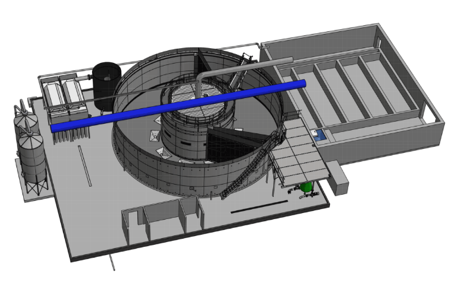

Thereafter the group headed to the village of Stakroge, where a specific 4m tall circular ModulRAS production facility also functions as a demonstration and test center for Assentoft Aqua,whilst the production company Stakroge Fiskproduces approximately 400 tons of rainbow trout per year with only 1.5 persons employed on site. The portion-size fish with an average weight of 330g have been produced since 2017 and are sold as ASC-certified in a total of 3-4 batches a year. There is a mortality rate of less than 1% and no antibiotics are used during the production. The plant uses the water from its own bore hole and this water can also be used to reduce the water temperature in the RAS plant.

The ModulRAS concept is based on divided walls between the cleaning section and the grow out section. The cleaning section is situated centrally in the plant, surrounded by a circular basin which, in principle, acts as one endless raceway. The circular basin is partitioned into compartments with moveable grids so that the water volume in the individual compartments can be regulated according to the fish density.

In conjunction with harvesting, the volume of water can be reduced in one compartment, freeing up space for another compartment. The design focuses on effective solutions for fish production using less ground area than traditional raceway RAS production and with a better water cleaning system. Apart from the drum filters there are 2 bioreactors with moving-bed technology and all water is circulated through the cleaning system each 30 minutes. Advantages of the design are: pipe and cement savings compared to traditional RAS design, fast and easy installation (delivered on pallets), low cost per ton production, space and energy saving and high productivity.

On the 23rdof May the InnoAquaTech group was welcomed to the DTI test facility for food, feed and biomass extrusion and pelleting at Sønder Stenderup. There we were presented with information about the capacity and uses of the pilot and development plant, where new formulae, ingredients and additives for animal and fish feed can be tested in a controlled atmosphere. The facility offers the possibility for pre-treatment, grinding (10kg-5000kg/hour), pelletizing (few grams to 6000kg/hour), extrusion (10kg-3000 kg/hour) coating (15kg – 600 kg/batch), biomass drying (10kg-3000kg/hour) as well as offering customized operator courses and analysis.

The final company visit for the InnoAquaTech group was Aller Aqua in the village of Aller near the town of Christiansfeld. The group was shown the great hospitality of CEO and Owner, Hans Erik Bylling and Aller Aqua Group R&D Director, Dr. Hanno Slawski. Aller Aqua has a global outreach and a strong reputation for responsible production, high quality feeds and food security procedures. Aller Aqua has invested in establishing local feed factories together with local investors in many countries, working closely with communities in those countries to help them raise their standards of living and providing good jobs. Aller Aqua has its own R&D testing facilities in Büsum, Germany and lively discussions were held about innovation in feed ingredients that are emerging from the desire to improve sustainability and welfare as well as increasing resource efficiency in general. The results of the four InnoAquaTech pilot demonstration projects and future collaboration potential was also discussed.

Overall, the study visit has shown that Denmark comprises a very large capacity for large-scale RAS aquaculture with top technological solutions, supporting the growth of RAS aquaculture in the South Baltic Region.